This Electronic Manufacturing Process is Helping Your Business

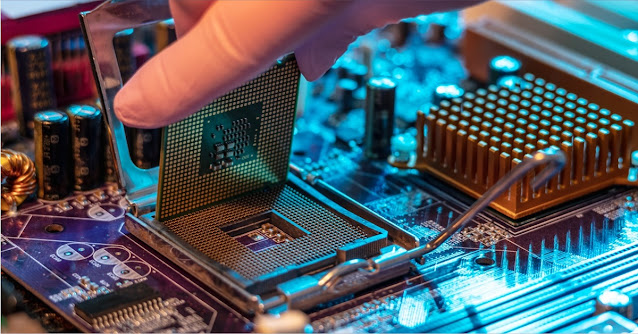

The electronic manufacturing process is essential knowledge for OEMs, PCB designers, and product designers. The step-by-step process influences the final product's reliability, longevity, and design. If you're developing a product and want to know where it fits into the manufacturing process, this article will tell you everything you need to know. An electronic manufacturing process is a way to produce electronics using computers. It has been around since the 1980s. Today, it is still widely used. What is the electronic manufacturing process? It is the process of creating a product that uses electronics. Electronics are used in almost all products, from cars and computers to cell phones and televisions. The manufacturing process differs for different product types, standard requirements, product grades, sizes, usage, and shape requirements. When it comes to manufacturing electronic products, PCBs are the foundation of any design. They're used to connect all of your compon...