This Electronic Manufacturing Process is Helping Your Business

The electronic manufacturing process is essential knowledge for OEMs, PCB designers, and product designers. The step-by-step process influences the final product's reliability, longevity, and design. If you're developing a product and want to know where it fits into the manufacturing process, this article will tell you everything you need to know.

An electronic manufacturing process is a way to produce electronics using computers. It has been around since the 1980s. Today, it is still widely used.

What is the electronic manufacturing process?

It is the process of creating a product that uses electronics. Electronics are used in almost all products, from cars and computers to cell phones and televisions. The manufacturing process differs for different product types, standard requirements, product grades, sizes, usage, and shape requirements.

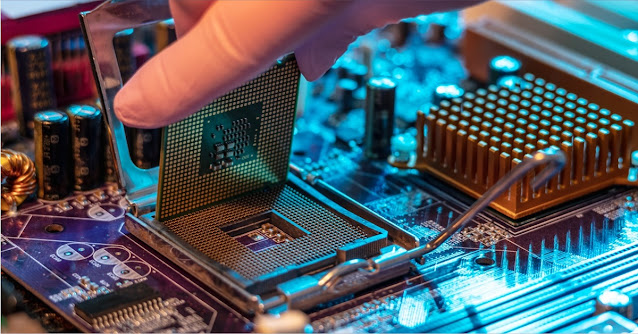

When it comes to manufacturing electronic products, PCBs are the foundation of any design. They're used to connect all of your components and make them work together as one unit. PCB Manufacturiong is the core part of many EMS Companies that develop products and provide services in electronic manufacturing services.

Mefron technology following below electronic manufacturing process.

The Process:

As a manufacturing process, the electronic pcb manufacturing and assembly process is complex. However, it is critical to understand what goes on in the background of your device so that you can be confident that it was constructed with care and attention to detail.

The first step in creating an electronic product involves creating a design for how it should look and function. Designing is done by drawing sketches or using 3D modeling software, then creating CAD models of these shapes using programs. Finally, engineers use these designs as templates for manufacturing equipment such as injection molds or CNC routers when making prototypes before moving onto production runs once testing shows that everything works together without problems.

Designing your product

When designing a product, it's important to remember that no two products are alike. The design concept has to be unique and satisfy all the product requirements.

Designing can do using computer software or 3D printing as tools for designing your product, but ultimately, the best way to get started is by thinking about what would make the best possible version of what you want—and then making it happen!

Prototyping your design

When designing a product, having something that can be used as a reference, such as a prototype, is essential. A prototype is useful not only for testing but also for determining how well your design will operate and what changes need to be made before manufacturing begins.

Testing the prototype

Once the prototype is ready, it's time to test. The first thing you'll want to do is make sure that the product works as expected. This means testing for functionality, durability, safety, and quality control. Testing involves checking a product against certain criteria before it goes into production, giving you confidence in your design and production processes. Testing can be done at any stage of development.

Manufacturing your final product

Electronics Manufacturing process your final product can be done in-house or by outsourcing it. Outsourcing allows manufacturers to focus on other areas of their business and leave quality control, cost control, and other details like production scheduling up to someone else.

System Assembly

System assembly is the final stage of the manufacturing process and involves putting together the components and devices into a working system. It may involve soldering, gluing, or screwing.

The assembly process begins with components being picked up from suppliers, placed in appropriate packaging, and then sent to your factory. Once you receive them at your facility they are inspected to ensure they meet quality standards before being transferred into inventory for further processing or testing if needed.

Conclusion

The electronic manufacturing process is a complicated one, but it is important to understand. It can be frustrating because you can't always see what's going on behind the scenes and there are so many steps involved in making a product that you may feel lost at times! However, with some patience and persistence, we promise that if you keep at it long enough, everything will turn out okay in the end.

Meet India's one of the top Electronic manufacturing service providers, Mefron Technology is hi-tech facility can handle all EMS requirements including PCB manufacturing, plastic injection molding testing, supply chain management, etc.

Comments

Post a Comment